Standard grade

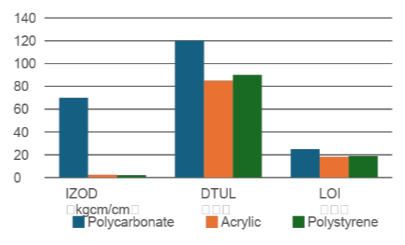

Polycarbonate resin is one of the “Big 5” general-purpose engineering plastics, along with polyamide, polyacetal, polyester, and modified polyphenylene ether, and is the only one among them that possesses transparency. While there are other transparent resins like acrylic and polystyrene, polycarbonate resin stands out due to its superior impact resistance, heat resistance, and flame retardancy. These unique properties make polycarbonate an essential resin material used across a wide range of industries and applications, such as household items, building materials, electrical products, optical devices, and automobiles.

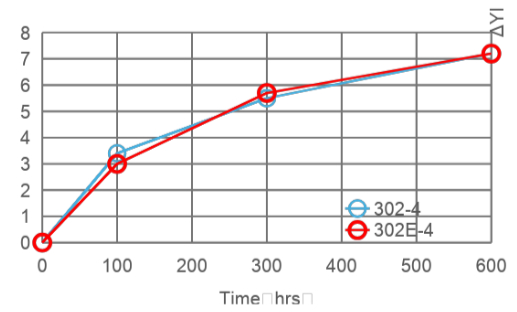

Polycarbonate resin is known for its excellent weather resistance, but to further prevent discoloration due to exposure, Sumika Polycarbonate offers the 302 and 303 series, which have enhanced weather resistance. Recently, under EU REACH regulations, the ultraviolet (UV) absorbers used in some materials were added to the SVHC (Substance of Very High Concern) candidate list. In response, Sumika Polycarbonate has introduced the E Series, which offers comparable performance to the traditional grades while being free of SVHC-listed substances, in addition to the long-established 302 and 303 series.

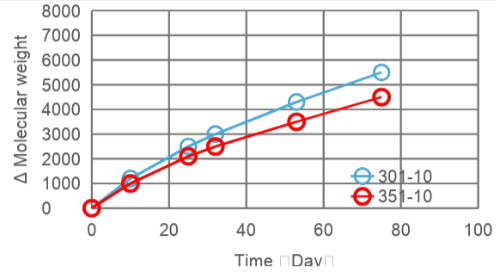

Although polycarbonate resin is known for its excellent transparency, flame retardancy, and impact resistance, long-term exposure to high temperatures and high humidity can lead to hydrolysis, which results in a decrease in molecular weight. The 351 series has been developed to provide improved hydrolysis resistance while maintaining the same high performance as the 301 series.

This makes the 351 series particularly suited for applications in environments with prolonged exposure to moisture and heat, where maintaining material strength and durability is critical.

Features of standard grade

Characteristics of the Big 5 General-Purpose Engineering Plastics

| Transparency | Water absorbency | Flame resistance | Chemical resistance | Abrasion resistance | |

| PC | ◎ | ○ | ◎ | △ | △ |

| PA6 | × | × | ○ | ○ | ○ |

| POM | × | ○ | × | ○ | ○ |

| PBT | × | ○ | × | ○ | △ |

| Modified PPE | × | ◎ | ○ | ○ | △ |

Performance Comparison of Transparent Resins

Comparison of Various Properties

| Properties | Test Method | Unit | 302-4 | 302E-4 |

| Transmission【2mm】 | ISO13468 | % | 89 | 88 |

| Haze【2mm】 | ISO14782 | % | 0.4 | 0.4 |

| Tensile Stress(Yield) | ISO527-2 | MPa | 60 | 60 |

| Tensile Strain(Break) | ISO527-2 | % | 110 | 110 |

| Charpy Notched Impact Strength | ISO179 | kJ/m2 | 80 | 80 |

| Deflection Temperature Under Load【1.80MPa】 | ISO75-2 | ℃ | 130 | 130 |

Color Change After Weathering Tests

Comparison of Various Properties

| Properties | Test Method | Unit | 301-10 | 351-10 |

| Transmission【2mm】 | ISO13468 | % | 89 | 89 |

| Haze【2mm】 | ISO14782 | % | 0.4 | 0.4 |

| Tensile Stress(Yield) | ISO527-2 | MPa | 60 | 60 |

| Tensile Strain(Break) | ISO527-2 | % | 110 | 110 |

| Charpy Notched Impact Strength | ISO179 | kJ/m2 | 75 | 75 |

| Deflection Temperature Under Load【1.80MPa】 | ISO75-2 | ℃ | 126 | 126 |

Molecular Weight Decrease in Hot Water Immersion (95°C)

Usage

Contact Us

If you have any questions about our products or would like to know more about our products, please contact us using the form below.